The shift toward electric vehicles (EVs) represents a significant leap forward in achieving sustainability and reducing carbon emissions. However, this transition also brings forth new challenges and opportunities in vehicle design and the materials used in manufacturing to keep these vehicles lightweight, yet safe and durable.

Electric Vehicle Lightweighting

For several years, the automotive industry has prioritized lightweighting, a process of reducing vehicles’ weight by using lighter materials. However, this concept is no longer just about using lighter materials — it’s now about smart design and material selection that contribute to overall vehicle efficiency without compromising safety or performance.

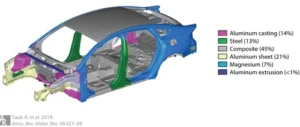

Historically, lightweighting efforts primarily involved substituting aluminum for steel. The current consensus among manufacturers is that an optimized multi-material design represents the industry’s future.

Multi-Material Designs in EV Manufacturing

Multi-material design is now recognized as a key strategy for the EV industry and stands at the forefront of the lightweight design movement. It is widely acknowledged that incorporating a variety of materials with distinct properties, such as high carbon steel, aluminum, magnesium, and polymer composites, into a design results in improved product performance overall.

For example, high-strength steel, such as high-carbon steel, remains the preferred material for components where safety is critical, such as housing to protect the battery in the event of a crash. High-strength steels are also often used for body panels and structural members where durability is key. Conversely, aluminum can help remove weight and bring corrosion resistance to areas such as the chassis, floor pan, and body panels.

By selecting the material with the most suitable properties for specific auto components, manufacturers can enhance functionality, safety, aesthetics, and end-of-life recyclability.

Source: Annual Reviews Volume 49: Materials for Automotive Lightweighting

The Role of High Carbon Steel in EV Manufacturing

High carbon steel, known for its high strength, durability, and resistance to wear and tear, plays a pivotal role in the auto industry, including in EV manufacturing. Despite the growing popularity of lighter materials, high carbon steel remains an essential material for its:

Strength and Safety

High carbon steel has a high strength-to-weight ratio and tensile strength. This gives it the ability to withstand greater pressure without bending or deforming. Manufacturers can ensure that vehicles meet stringent safety standards by incorporating high carbon steel in critical areas.

Durability

Parts manufactured using high carbon steel will be less susceptible to corrosion or extreme weather conditions. Compared with low carbon steel, high carbon steel won’t wear out as quickly under adverse factors.

Flexibility

High carbon steel easily forms into many shapes and sizes without breaking. Once in the configuration desired, apply heat-treat, and the steel will acquire “memory.” It maintains its shape even after being applied.

Aesthetics

Because of the strength and durability of high carbon steel, parts and fasteners can easily be hidden to allow for aesthetic appeal without sacrificing strength.

Innovation in Manufacturing

As the EV industry flourishes, innovations in design and materials continue to evolve. This includes new advanced high-strength steels that provide even greater strength with less material. New EV designs continue to be released, and high carbon steel will remain part of the multi-material design as it offers the perfect blend of strength and durability for structural integrity and safety.

Three D Metals: The Largest Distributor of High Carbon Steel in North America

With the automotive industry changing rapidly, it’s important to have a metals partner that is flexible, attentive to your needs and shares a commitment to sustainability. At Three D Metals, we are invested in sustainability with dedicated processes and solutions that reduce our carbon footprint and promote a greener future.

Reach out to us today for a custom quote!