This article, originally published in 2021, has been updated with the latest information.

The metals industry continues to be at the forefront of the sustainability movement, driven by tight margins and an increasingly competitive landscape. “Sustainability” goes far beyond simply recycling waste materials or packaging. Instead, it’s a method for viewing one’s business practices and their impact on both the bottom line and the wider world.

Here, we explore sustainability trends in the metals industry that we anticipate will continue to accelerate in the year ahead.

RECYCLING

More emphasis is being placed on the recycling of metals and creating a circular economy. Instead of mining new raw materials, companies are seeking to recycle waste materials and reuse metals in an endless loop, significantly reducing their environmental impact.

This is especially true with copper, where customers are bracing for the copper shortage predicted in the next few years. Copper demand is set to skyrocket from today’s 25 million metric tons (MMt) to an unprecedented 50 MMt by 2035, according to S&P Global’s The Future of Copper report.

This heightened awareness of recycling is driven not only by the desire to recover scrap value amid copper’s volatility but also by the collective ambition to contribute to a sustainable future, as outlined in The Paris Agreement.

Recycling alone won’t be enough to overcome the predicted supply/demand gap, but it’s a step in the right direction economically and for sustainability efforts.

At Three D Metals, we recycle 100% of our metal processing waste and also offer a skid recycling program to reuse old skids returned by customers. When the skids can’t be used anymore, they are thrown into our furnace, which heats about 50% of our plant in the winter.

Most of our ferrous metal is shipped with metal cores, making recycling easier for our customers. Instead of throwing out a cardboard core, customers can simply throw the metal core in the hopper and reuse it.

CLEANER PACKAGING PROCESSES

The increasing cost of freight, nearly 25% in 2022, has been a leading driver for packing reductions and innovations in the metals industry.

Consolidation of packaging items, custom packaging solutions that eliminate the need for excessive waste, and choosing reusable packaging options such as wood, paper, or metal can all slash expenditures on both freight and packaging.

This is a trend we have followed here at Three D Metals, as well. We regularly evaluate how we package and ship items to reduce the amount of packaging we use and reduce our carbon footprint. Any packaging we do use is 100% recyclable.

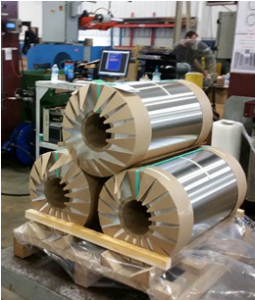

We also offer tripod packaging, which allows more coils to be packaged per skid. Tripod packaging is ideal for customers who like small, wide-width coils. This reduces product footprint on the shop floor as well as freight costs.

SUPPLY CHAIN EFFICIENCY AND TRANSPARENCY

As we saw in 2020 with the pandemic and in early 2021 with the blockage of the Suez Canal, the global supply chain can be incredibly fragile. This has inspired a trend for metals suppliers to focus on establishing local partnerships they trust and which are transparent.

At Three D Metals, we place a strong emphasis on:

- Keeping our customers informed about market shifts and supply chain issues.

- Communicating proactively and regularly.

- Supporting them in planning for the future.

Our metals newsletter is one such resource that provides updates on industry trends and market dynamics.

MORE ABOUT SUSTAINABILITY AT THREE D METALS

At Three D Metals, we take sustainability seriously. Our commitment to sustainability began with the installation of a wind turbine at our headquarters. At 121 feet high, the turbine saves an estimated $21,000 a year in energy costs. We also have a new sustainability initiative in the works and ready to roll out in 2023.

Discover more about our commitment to sustainability at Three D Metals: